India’s 1.4 Gt Carbon Bomb – Can Innovation Outpace Emissions?

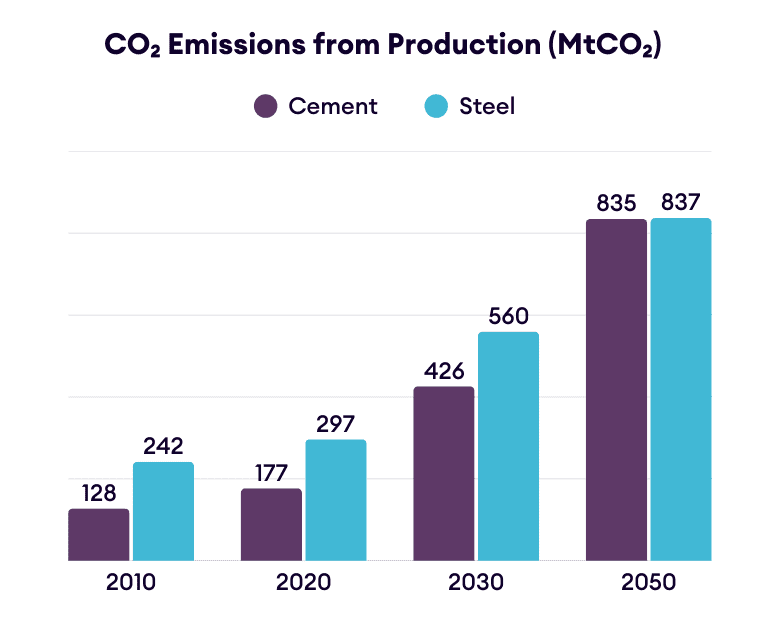

India's infrastructure expansion could trigger a massive emissions surge, with cement and steel production alone projected to release 1.2-1.5 gigatons of CO₂ annually by 2040 – triple current levels.

This alarming growth threatens to undermine the nation's climate commitments while global competitors race to decarbonise.

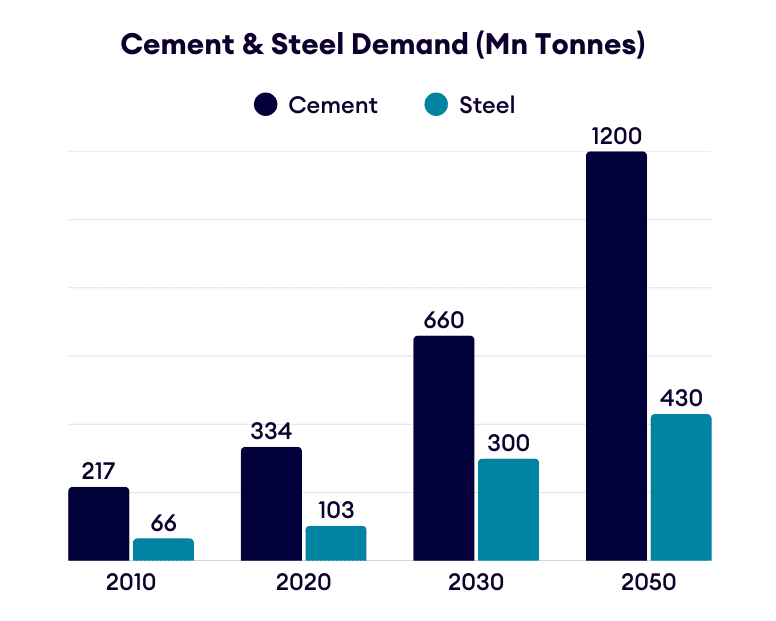

India's development demands require 660 million tons of cement and 230 million tons of steel annually - materials responsible for 16% of national CO₂ emissions today (500Mt combined).

This situation is critical because growth is non-negotiable for urbanisation and economic progress. Also, these are hard-to-abate sectors, which implies that curbing emissions is harder

Hence, emissions from these sectors are projected to triple to 1.2-1.5 gigatons by 2040, contributing to 25% of India's total emissions!

Why are Steel and Cement such a problem?

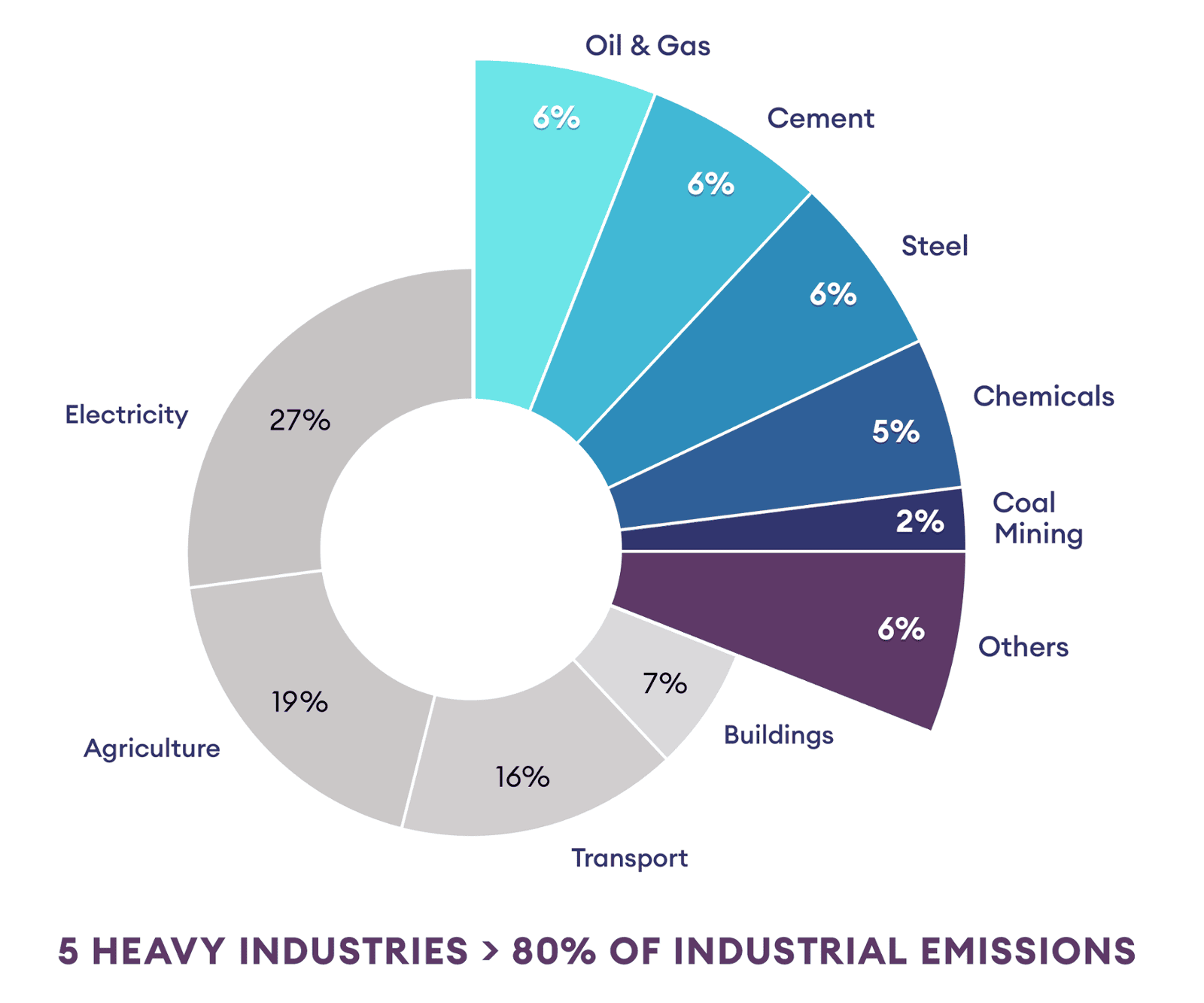

Hard-to-abate sectors, including steel, cement, chemicals, aviation, shipping, and heavy-duty transport, account for 31% of global greenhouse gas emissions and are projected to grow by over 50% by 2050 under business-as-usual scenarios.

Why are they hard to abate?

- Process Emissions: Cement production emits CO₂ during limestone calcination (60% of emissions). Steel manufacturing releases 1.9 tons of CO₂ per ton via coal-based blast furnaces.

- Energy Intensity: Industrial processes require extreme heat (>1,400°C), which renewable electricity struggles to provide efficiently1.

- Cost Barriers: Green hydrogen ($4-6/kg) remains 2-3x costlier than fossil fuels. Carbon capture technologies add 30-50% to operational costs1.

Opportunities for Startups

India’s infrastructure boom creates significant opportunities for startups focused on decarbonising hard-to-abate sectors: Green Cement: $3.28B market (5.85% CAGR) & Green Steel: $88.4B market (56.6% CAGR).

- AI-Driven Process Optimization: Leveraging deep reinforcement learning and neural networks to dynamically optimize kiln temperatures, raw material mixes, and energy use, reducing waste and emissions in real time.

- Green Hydrogen Production for Steel: Developing cost-efficient, scalable PEM electrolyzers to supply clean hydrogen for carbon-free steelmaking.

- Supplementary Cementitious Materials (SCMs): Pioneering methods to convert industrial waste or natural materials into high-performance clinker alternatives, slashing cement’s carbon footprint.

- Carbon Capture & Utilization (CCU) for Cement: Deploying advanced CO₂ capture systems at cement plants and repurposing emissions for use in concrete or other applications.

- Electric Kiln Technologies for Cement: Designing breakthrough electric heating systems capable of ultra-high temperatures (1,400°C+) to eliminate fossil fuel reliance in cement production.

The cement and steel sectors present critical challenges for India's climate commitments but also offer substantial opportunities for innovation. As the country balances growth with sustainability, technological solutions in these hard-to-abate sectors will play a decisive role in achieving a lower-carbon future without compromising development goals.